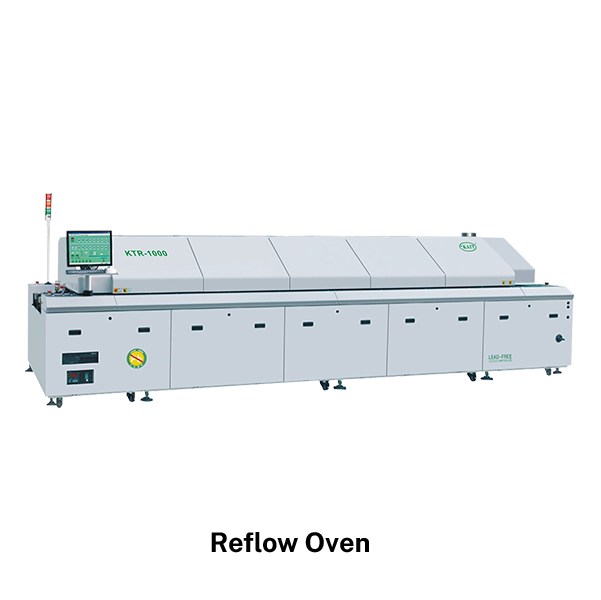

Brand: KAIT, China

REFLOW OVEN

- Meet various high-class requirements for lead-free reflow process

- Patent hot air system, using hot air convection conduction heat faster, more efficient compensation

- PLC+PID closed-loop control to achieve high precise temp. control and repeatable profiles

- Dual temp. sensors and dual safety control, the system shall cut off the power while abnormal case occurred

- Various alarm function: over temp. alarm, abnormal speed alarm, and PCB dropped alarm

- Modular design to get quick and simple maintenance so that reducing the maintenance time and cost

- The rail is dealt with the hardened process to make it more stability

- Perfect cooling effect with up 3 and bottom 3 cooling zones

- Adopted thick aluminium plate as rectifier of hot air, The ideal energy storage effect is obtained and the heating speed is faster

- Optional nitrogen system with oxygen concentration as low as 300ppm and nitrogen consumption as low as 10m3/hr

We’d love to help you boost your production efficiency. Contact us.

_Specifications_

| MODEL | TOP-1000 | TOP-1200 | TOP-1000D | TOP-1200D |

| HEATING SYSTEM PARAMETER | ||||

| Heating zones | Up 10/ bottom 10 | Up 12/bottom 12 | Up 10/bottom 10 | Up 12/bottom12 |

| Heating length | 3892mm | 5675mm | 3892mm | 4675mm |

| Cooling zones | Up 3/bottom 3 | |||

| Cooling system | Air cooling and optional water cooling system | |||

| Exhausting flow | 11-12 M³/min X 2 exhausting | |||

| CONVEYOR SYSTEM | ||||

| PCB max width | 400mm(option 460mm) | 300mmX2(single rail 50-450mm) | ||

| Rails structure | Overall sectional type | |||

| Chain structure | Double buckle for preventing pcb jammed | |||

| Conveyor direction | L-R(option R-L) | |||

| Fixed rail side | Front rail fixed(option back rail fixed) | 1/4 fixed and 2/3 moveable or 1/3 fixed and 2/4 moveable | ||

| Conveyor height | 900±20mm | |||

| PCB transporting | Chain+ melt(option chain+ center supporting system) | |||

| PCB height clearance | PCB up 30mm,bottom 30mm | |||

| Conveyor speed | 300-2000mm/min | |||

| Auto chain lubrication | Multi-lubrication mode can be chosen | |||

| CONTROL SYSTEM PARAMETER | ||||

| Power supply | 3PH,380V 50/60Hz(optional 3ph,220V 50/60Hz) | |||

| Total power | 80KW | 96KW | 83KW | 99KW |

| Starting up power | 36KW | 42KW | 38KW | 44KW |

| Working power | 10KW | 11KW | 11KW | 12KW |

| Warm-up time | Approx. 20 min. | |||

| Temp. control range | Room temp.—300C° | |||

| Temp. control mode | Closed loop PID controlled with SSR drive | |||

| Temp. control accuracy | ±1 C° | |||

| PCB temp. deviation | ±1.5C° | |||

| Data storage | Process data and status can be in storage | |||

| Abnormal alarm | Extra high and low temp. | |||

| Color tower | Yellow,red,green 3 color lamp | |||

| MACHINE PARAMETER | ||||

| Dimensions(LXWXH) | 6300X1430X1530 | 7050X1430X1530 | 6300X1680X1530 | 7050X1680X1530 |

| Weight | Approx.3020KG | Approx.3310KG | Approx.3060KG | Approx.3360KG |

| Color | Computer grey | |||

| Rectfying plate | thick aluminium plate | |||

| OPTION | ||||

| N2 configration | “-N”N2 config. With closed construction and pipe, flow meter, water chiller, oxygen analyzer | |||

| N2 consumption | Standard width machines(400mm): 300-1000PPM,10-20m³/hr; More big width machines(610mm): 500-1000PPM,25-30 m³/hr | |||

| Center supporting | Without melt | |||