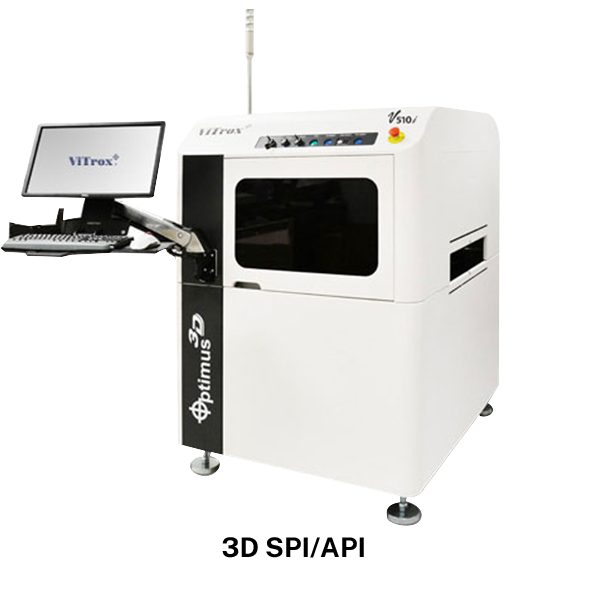

Brand: ViTrox, Malaysia

3D SPI/API

- ViTrox’s SPI is equipped with world fastest Gerber switching which supports 74x, 274d & CAD input

- It is easy to use and convenient for editing

- SPI supports manual programming even without the Gerber database

We’d love to help you boost your production efficiency. Contact us.

_Specifications_

| ITEM | Model | |||

| X5L | X6L | X8L | ||

| Metal Mask | rame Size | 650*550mm | 650*550mm | 1000*1000mm |

| 736*736mm | 736*736mm | |||

| Print Origin | Center | |||

|

PCBA | Min Size | 50*50mm | ||

| Max Size | 510*510mm | 610*510mm | 800*400mm | |

| Thickness | 0.4 – 6.0mm | |||

| Weight | Max 3.0Kg | Max 4.0Kg | Max 5.0Kg | |

|

Conveyor | Pass Line | 920±30mm | ||

| Stage | Single Stage | |||

| Belts | Flat Belts(Anti-Static) | Time Belts | ||

| Clearance | Less Than 5.0mm both side | |||

| Components | +20mm / -20mm | |||

| Clamping | Edge / Vacuum Chamber / Multi-Point Clamp / Top Clamp | |||

| Width Adjust | Motorized Width Adjustment | |||

| Cycle Time | PCB Moving | 7.5 Sec | 8.5 Sec | 10.5 Sec |

| Model Change | Less Than 10 min | |||

| Accuracy | Repeatability | ±15 um | ||

| Squeegee | Material | Metal / Urethane | ||

| Direction | Front <-> Rear | |||

| Interface | SMEMA | |||

| Power | 1Ø 200-230(VAC), 50/60(Hz), Less Than 2.0 KVA | |||

| Pneumatic | 5-6 (bars) , 10Ø Air-hose,Max 150 l/min | |||

| Dimension | W*D*H | 1428*1394*1548 | 1600*1530*1548 | 1750*1530*1548 |

| Weight | Approx | 950 Kg | 1000 Kg | 1100 Kg |

Similar Products

_SMT Line Solutions_

In the realm of electronics manufacturing, ensuring precise solder paste application is essential for the reliability and functionality of printed circuit boards (PCBs). At Kyoritsu Electric India, we offer state-of-the-art 3D solder paste inspection machines that provide advanced and accurate inspection solutions. Our 3D solder paste inspection machines are designed to streamline the inspection process and optimize the quality control of solder paste deposition.

Equipped with cutting-edge technology, our 3D solder paste inspection systems utilize high-resolution cameras and sophisticated algorithms to analyze the solder paste deposits with exceptional precision. These machines can capture detailed 3D images, allowing for a comprehensive inspection of solder volume, height, shape, and alignment. With this level of review, potential defects such as insufficient or excess solder paste, bridging, and misalignment can be quickly identified and rectified, ensuring optimal solder joint quality.

Our solder paste inspection machines are built for reliability and efficiency. They offer fast inspection speeds without compromising accuracy, enabling seamless integration into your production line. With user-friendly interfaces and intuitive software, operating our machines is straightforward, facilitating efficient inspection processes.

By investing in our advanced solder paste inspection equipment, you can significantly enhance the quality control of your PCB assembly. Our 3D solder paste inspection machines provide unmatched precision and reliability, minimizing defects and optimizing production yield.